Oxy acetylene welding is a welding process manually in which the surfaces to be joined which is warming to melt by a gas flame oxyacetylene with or without filler metal where the connection process without emphasis.

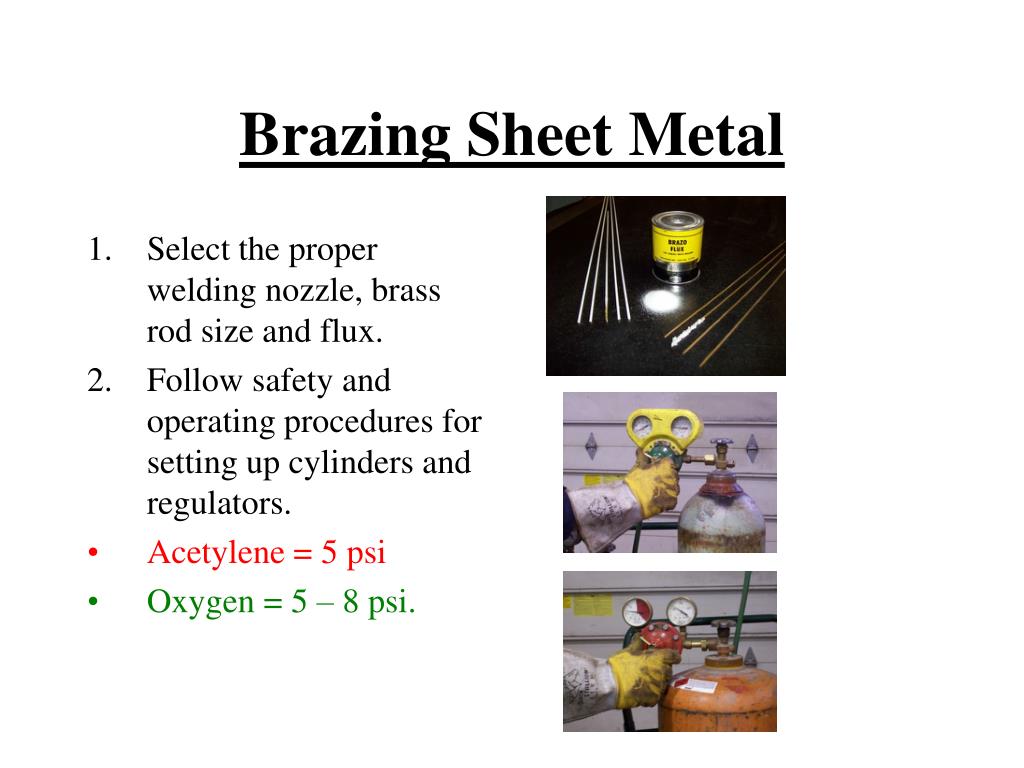

Brazing sheet metal oxy acetylene.

In torch brazing a variety of fuels are available natural gas acetylene propane propylene etc combusted with either oxygen or air.

Slowly add oxygen flame will sharpen and elongate.

The oxy acetylene flame generated by mixing oxygen and acetylene gases to fuel a torch is infernally hot about 6 300 degrees f at the cone tip of a neutral flame.

Oxy acetylene gas welding rods the oxy fuel process is considered old school.

If there is too much acetylene flame breaks away from the tip.

Oxidizing excess oxygen to acetylene burning ration with on acetylene feather and makes a harsh hissing sound least used because it oxidizes metal but is used for braze welding with a bronze rod neutral x burns equal amounts of oxygen and acetylene and has a clean clean edged inner cone the most used flame for oxyacetylene applications.

If the pressures are adjusted correctly for the size of the torch opening there should be little to no hissing noise coming from the torch.

Safety equipment plus procedures for safe operation.

At the end of the.

And this welding process is still very popular today mainly because it does not require much equipment and does not require power.

Brazing is a form of non fusion welding.

Apply the brazing rod to the joint while continuing to heat the metal surfaces.

Oxy acetylene welding oxy acetylene welding and sheet metal.

Continue opening the oxygen until the acetylene cone disappears into the white inner cone.

After brazing use a wire brush to clean the brazed surface to remove any oxidation or residue.

Continue to add oxygen until neutral flame is established.

Read our general safety precautions before starting your project.

Heat the joint where the two pieces of metal will meet until the joint glows.

For large areas heat portions of the joint to temperature and then move to the next adjacent area.

The most popular is still the oxy acetylene mixture.

But there are times when you may find uses for torch welding and brazing techniques.

Once the torch flame is adjusted correctly you are ready to braze.

Jeff shows how to braze using an oxygen and acetylene how to set your gas mixture and the correct way to light your torch.

In most shops acetylene gasis combined with oxygen to produce the torch flame.

In addition to the purposes of welding connecting gas welding can also be used as preheating brazing cutting and hard facing.

When it comes to safely brazing with oxy acetylene torches let s look at two important aspects.